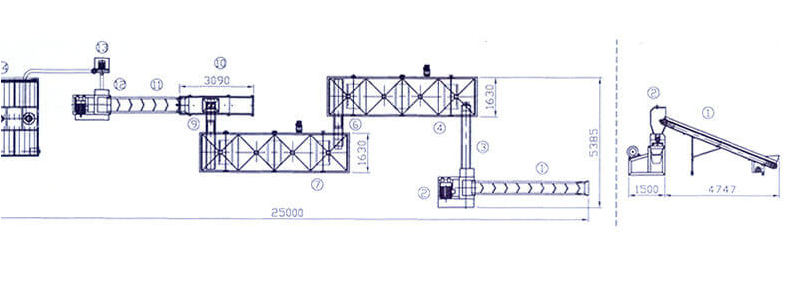

Waste Plastic Recycling Plant: Double De-gasing Model

What Are the Benefits of Song Ming's Waste Plastic Recycling Plant with Double De-Gasing Model?

Song Ming's waste plastic recycling plant, featuring the double de-gasing model, is a cutting-edge solution designed to optimize plastic recycling efficiency and ensure long-lasting performance. At the heart of the double de-gasing model is equipped with a dual de-gassing system, which is highly effective in removing impurities, contaminants, and unwanted gases from plastic materials. The result is a recycled plastic material that consistently meets the most stringent quality standards, rendering it eminently suitable for a diverse array of applications. Double degassing is a valuable technique for industries that require high-quality, gas-free materials. Its two-stage process not only ensures superior gas elimination but also acts as a catalyst for elevated product quality, unwavering consistency, and substantial environmental benefits.

What Are the Applications of the Double De-gasing Model?

The double de-gassing model, with its enhanced capability to remove impurities, contaminants, and unwanted gases, finds a wide range of applications in various industries. It plays a vital role in enhancing the quality, consistency, and environmental sustainability of recycled materials across a range of industries, supporting a more eco-friendly approach to plastic production and resource management. The double de-gassing model works for specific materials such as PP, LDPE, HDPE, LLDPE, PS, PS Foam Sheet, and ABS, etc. These applications demonstrate the versatility of the double de-gassing model in recycling and processing various plastic materials.

Song Ming: Innovative Plastic Recycling Technology for a Sustainable Future

Song Ming has full knowledge and experience to provide the technology for industry field friends to install a cost-effective and reliable installation to produce high-grade recyclables for excellent products further down the production chain. At Song Ming, we are not just a plastic recycling machine manufacturer; we are your partners in creating a sustainable future. With years of experience as a leading plastic recycling machine manufacturer, we bring unmatched expertise to your recycling endeavors. We are proud that we have engineered top-notch waste plastic recycling machines that seamlessly transform discarded plastics into valuable resources. By investing in double de-gasing model waste plastic recycling machine, we work towards a more sustainable and efficient plastic recycling process. Welcome to contact us for any info about our waste plastic recycling machinery anytime!

| Model | SM-90WPR | SM-100WPR | SM-120WPR | SM-150WPR | |

|---|---|---|---|---|---|

| Granulator | Model | SM-A15 | SM-A15 | SM-A20 | SM-A25 |

| Power | 15HP | 15HP | 30HP | 40HP | |

| Blower | Power | 3HP | 3HP | 5HP | 7.5HP |

| Screw Conveyor | Power | 3HP | 3HP | 3HP | 3HP |

| Size | 8'Φx3.2m | 8'Φx3.2m | 8'Φx3.2m | 8'Φx3.2m | |

| Main Extruder | L/D Ratio | 28:1 | 28:1 | 30:1 | 32:1 |

| Main Power | 30HP AC | 40HP AC | 60HP AC | 75HP AC | |

| Temp. Control | 5 zones | 6 zones | 7 zones | 8 zones | |

| Heating Capacity | 25KW | 30KW | 40KW | 50KW | |

| Hyd. Power of Die-exchang | 3HP | 3HP | 3HP | 3HP | |

| Power of Enforcing Hopper | 5HP | 5HP | 7.5HP | 7.5HP | |

| Production Capacity | 120-150 kg/hr | 150-180 kg/hr | 220-250 kg/hr | 280-350 kg/hr | |

| Sub-extruder | L/D Ratio | 1:8 | 1:8 | 1:8 | 1:8 |

| Power | VS 15 HP | VS 15 HP | VS 25 HP | VS 30 HP | |

| Heating Capacity | 15KW | 20KW | 25KW | 28KW | |

| Cooling Tunnel | Size | 8'x1.2'x1' | 8'x1.2'x1' | 10'x1.2'x1.1' | 10'x1.2'x1.1' |

| Pellet Cutter | Power | 3HP | 3HP | 5HP | 7.5HP |

| Blower | Power | 3HP | 3HP | 5HP | 7.5HP |

| Storage Barrel | Capacity | 1200L | 1200L | 1200L | 1200L |

- PP Ldpe Hdpe Lldpe Ps Abs Waste Plastic Recycling Plant

- PP Ldpe Hdpe Lldpe Ps Abs Small Type Waste Plastic Recycling Plant

- PP Ldpe Hdpe Lldpe Manual Side Feeding Waste Plastic Recycling Plant

- PP Ldpe Hdpe Lldpe Ps Abs Side Feeding Waste Plastic Recycling Plant

- PS Foam Sheet Waste Plastic Recycling Plant

-

Top Feeding

Top Feeding -

Top Feeding

Top Feeding -

Side Feeding

Side Feeding -

Side Feeding

Side Feeding